|

|

| Ash Handling System ! |

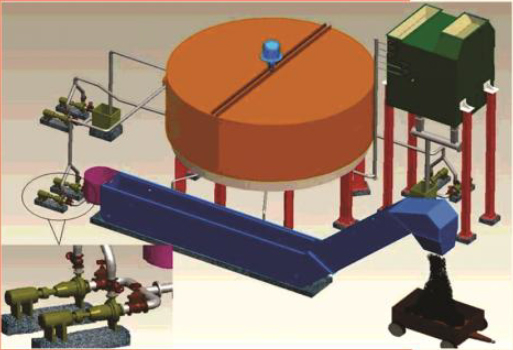

Viswakirti undertakes complete Design, Engineering, Supply, Erection, Testing and commissioning of ASH HANDLING SYSTEM |

| |

The use of fuels, either solids or liquids in the production of electrical power or industrial combustion processes, produces ash which is requires different type of handling. The fraction that accumulates at the bottom of the boiler, known as BOTTOM ASH, is generally in the form of pieces & requires mechanical, hydraulic or pneumatic conveying handling systems. |

| |

The more volatile part, known as FLY ASH, is dragged along by the gasses and deposited in the bottom of ash hoppers in the equipment downstream of the boiler, such as economizers, air pre heater, duct hoppers, electrostatic precipitators, stack hoppers and is normally removed in pneumatic conveying system or hydraulic systems. |

| |

Bottom Ash Systems

- Water impounded BA hopper with hydro jet pump or ash slurry pumps to discharge bottoms Ash up to ash slurry sump/ash disposal area.

- Dry type BA hopper with submerged scraper conveyor for continuous discharge of ash in wet slurry form.

- Hydro bin for bottom ash storage.

- Vacuum Pneumatic conveying utilizing mechanical exhausters(vacuum pumps), Vacuum produces, etc.

- Dense Phase Pneumatic conveying system.

Fly Ash Handling Systems

- Vacuum pneumatic conveying system by utilizing mechanical exhausters, (vacuum pump) vacuum producers and stream ejectors.

- Vacuum cum pressure pneumatic conveying system.

- Dense phase pneumatic conveying system to convey up to storage silos.

- Fly ash storage silos.

- Feeder ejector system and disposal of ash in slurry from up to ash slurry sump and further by AD pumps up to disposal area.

- Continuous discharge of fly ash in wet slurry from through flushing apparatus.

- Dry mechanical conveyors.

|

| |

|

|

|

|